Explaining Surf Lakes’ Commercial Design Updates

5 years of engineering, $10 million in R&D, and a journey that has captured the world’s attention

Surf Lakes’ 360-degree wave-generating machine has undergone significant evolution.

After five years of engineering, $10 million invested into research and development, and a journey that has captured the world’s attention, Surf Lakes’ commercial machine is primed to pump out perfect waves.

Upgraded to be quiet, efficient, reliable and prolific, the new machine boasts a sleek aesthetic that will serve as the iconic centrepiece of future Surf Lakes facilities. Built to meet the demands of the expanding global surf park market, Surf Lakes technology aims to set new standards for commercial wave generation.

The benefits of 1:1 prototyping

The prototype facility in Yeppoon achieved spectacular results, and the machine was pushed to its limits at 1:1 scale. Sometimes with great success and sometimes with less fruitful results. Each of these moments provided an opportunity to learn and improve. The testing provided invaluable insights, uncovered hidden weaknesses and allowed for precise refinements. The hands-on process provided Surf Lakes’ engineers with a deep understanding of how to optimise the machine for reliable, high-performance operation.

The result is a wave generator designed to withstand the rigours of commercial surf park operation and produce perfect, efficient waves, all day, every day.

What’s new?

With our full-scale prototype, the focus was on proving a concept. The commercial design built upon this and addressed the common feedback areas of aesthetics, noise, output and reliability.

Aesthetics

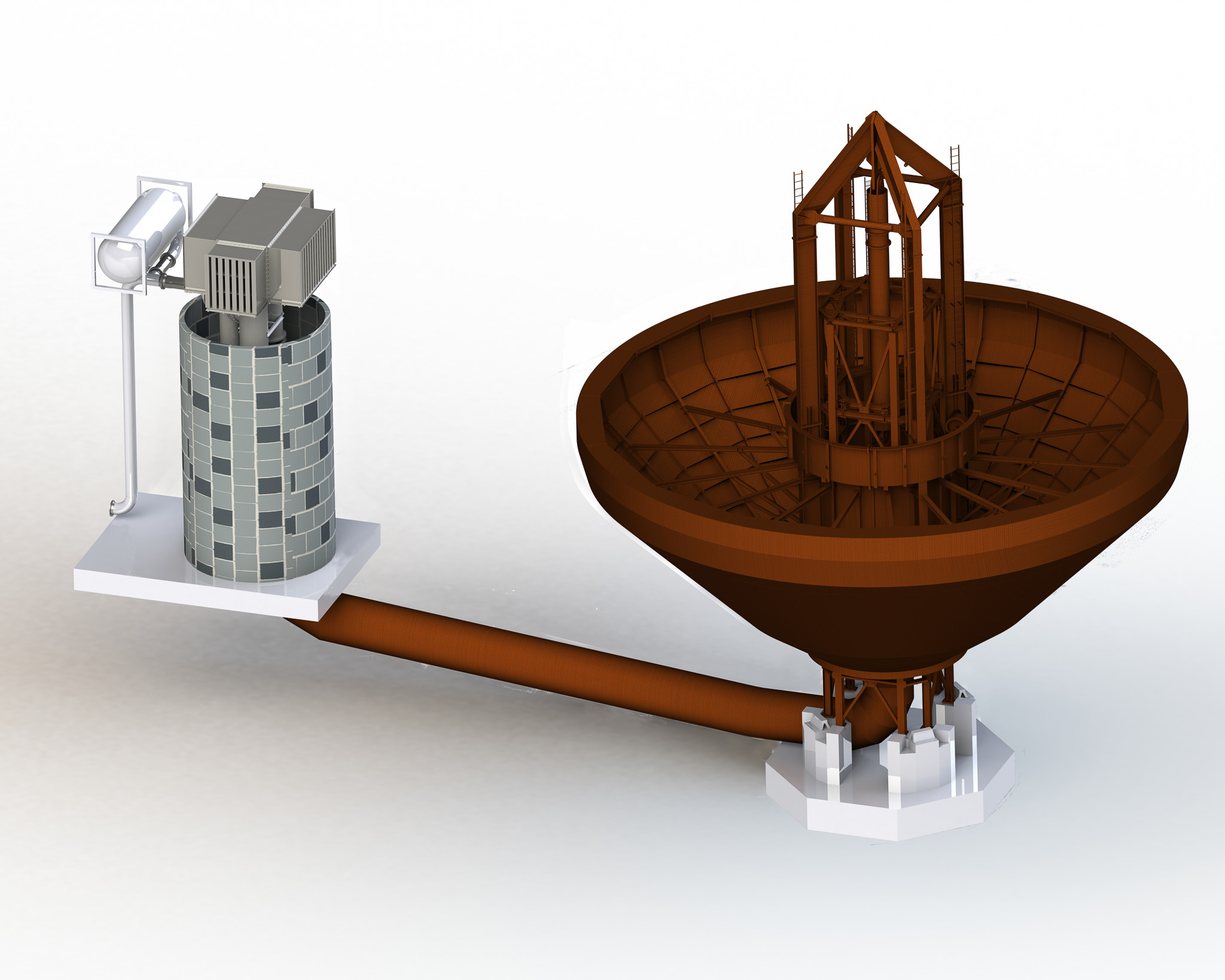

Before:

The prototype consisted of two main structures located in the lake.

The Concentric Wave Device (CWD) lifts up and down to produce waves.

The caisson structure, which remained static and housed the valving and pressure components. (It sits to the right of the machine in most clips and blows out the steam).

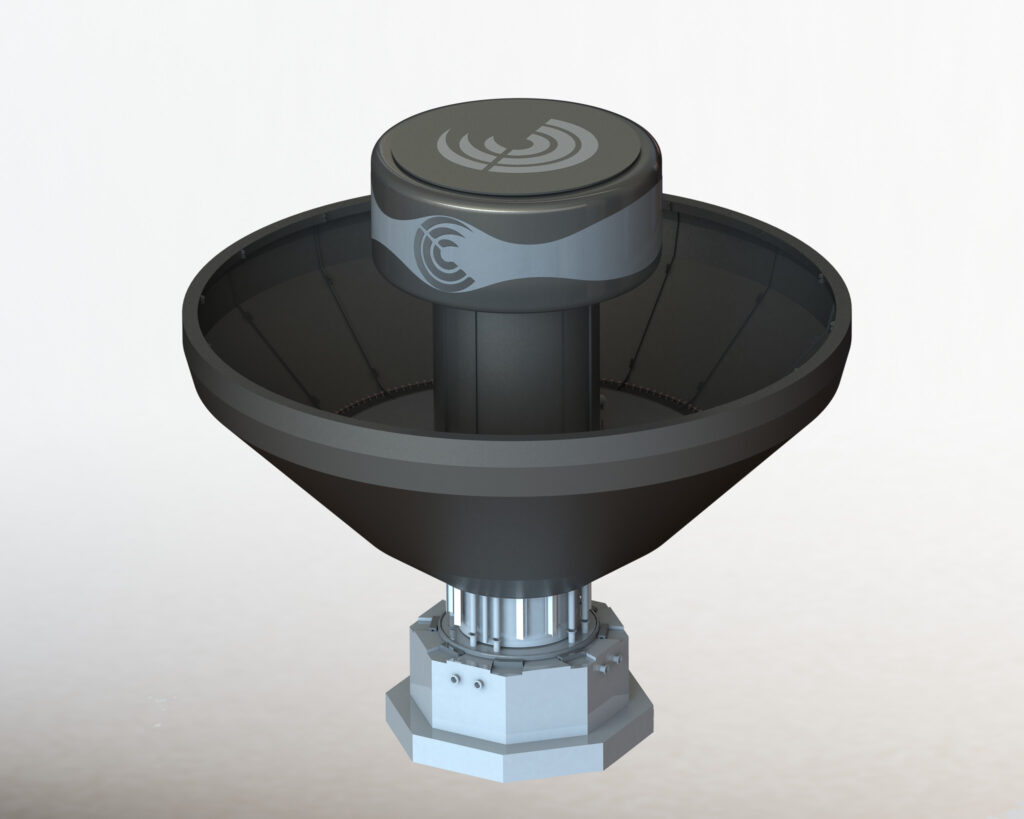

After:

The commercial machine has restructured the caisson components, fitting them efficiently within the CWD, consolidating the two structures into a single streamlined design.

Noise

Before:

The compressed air released from the caisson of the prototype was accompanied by a deep booming sound that raised concerns about commercial use in residential zones.

After:

The sound generated by this compressed air is now captured in a plenum before being discharged through an attenuated system inside the machine using baffle silencers. This works like a car muffler. As a result, the commercial machine will be quieter than the waves it pumps out.

Output

Before:

Compressed air used to operate the prototype was generated using mobile air compressors, which only produce about 1/5th of the compressed air flow compared to our commercial design.

After:

The machine uses commercial industrial air compressors with electric motors, offering 99.7% machine availability and can provide twice the efficiency compared to those at the prototype (and can be connected to renewable energy sources). The result is unmatched productivity, with a machine capable of producing a five-pulse set every 90 seconds.

It’s important to note that with Surf Lakes’ unique design, each pulse in a set produces a circular swell line that radiates out from the machine and hits the four A-Frame reefs positioned in each quadrant around the lake (and inside whitewash areas). This creates over 14 rides around the facility at once and caters to every ability level with each pulse.

8 rides across the 4 A-Frame reefs, and an average of 6 rides on the inside whitewash = 14 rides

Reliability

To create the most reliable machine possible, Surf Lakes’ engineering team undertook a rigorous process of component design and equipment selection, with components benchmarked through cyclic testing. Combined with learnings from the prototype, the system incorporates built-in redundancy and is supported by manufacturer and equipment warranties to guarantee machine reliability.

The mechanical and structural components of the CWD are engineered for durability, with a fatigue life rated at over 24 million cycles. These components are designed above relative normal operation, making them exceptionally robust, highly reliable, and largely maintenance-free. The result is a machine capable of supporting 12-hour daily operation for 50 years (or 24 hours a day for 25 years).

Just like the airline industry, essential components (such as high cycling valves) are designed with redundancy. This means affected components can be isolated without interrupting overall operation, and the components can be replaced during low-demand periods, i.e. overnight.

Examples and Benefits of Redundancy

For pneumatic components, redundant air flow paths have been implemented. Meaning if a valve or path fails, the affected path can be isolated without interrupting overall operation.

Another example of built-in redundancy is the three centrifugal air compressors. All three feed into a shared high-pressure air system. In the unlikely event that one compressor is unavailable, the remaining two can continue to pump out waves.

A similar principle applies to our electrical systems. The main switchboards’ electrical modules are hot-swappable, allowing for fast repair or replacement. Where electrical and control components have a shorter service life and are critical to operation, we’ve either designed redundant equipment for seamless failover or ensured replacements can be carried out rapidly, keeping downtime to an absolute minimum.

Summary of Upgrades

How it works

The commercial version works on the same core principles as Surf Lakes’ prototype machine. Stored, compressed air enters a pressure vessel, pressurising the hydraulic fluid (lake water), which pushes the CWD up out of the water. Once the air is released, the CWD falls back down with gravity and utilises water displacement to generate the swell. At the bottom of the stroke, the CWD buoyancy forces it to naturally rise from the water again, and at the precise time, another pulse of compressed air is applied to amplify the motion. This process is repeated to create a set of waves. At the end of the set, there is a short break to let the lake water settle and air pressure storage recharge before the next set starts.

Surf Lakes’ patented displacement technology is incredibly efficient. One full cycle (up and down) takes approximately six seconds; however, power is only applied for 1.5 seconds. As a result, when compared with conventional pneumatic wave systems, Surf Lakes is up to five times more energy efficient per wave produced.

Before:

The prototype wave machine arrangement consisted of two separated structures connected by a “U-tube.” The U-tube pipe filled with lake water provides the hydraulic fluid used to transfer the energy from the caisson pressure vessel to the CWD.

After:

The commercial machine operates on the same principles with a streamlined design that integrates the caisson and U-tube inside the CWD. By combining the pressure vessel, valves and U-tube into an annular arrangement, the machine benefits from reduced stress loads with improved dynamic response, resulting in a stronger, more reliable, and more efficient machine.

Surf Lakes’ research and development department and engineering team have been busy refining the design. The results have been very favourable. Successful operational testing, combined with insights from earlier scale model prototypes, has laid the foundation for an updated commercial machine design.

Recent cost estimates for this machine point to a reduction in cost even after significant upgrades to machine componentry and recent market trends.

Streamlined for better waves and improved customisation

By incorporating the caisson into the CWD, all structures have now been removed from Surf Lakes’ 360-swell line. This results in undisrupted swell travel from the CWD to the lake shores without structures or walls to disrupt conditions.

The Surf Lakes patented 360° lake bathymetry and channel arrangement creates uniform A-frame waves that form consistently around the lake, delivering the best wave quality in the industry.

360 degrees of symmetry allows for customisable arrangements, catering to varying site requirements with the flexibility to change shorelines and move onshore plant equipment locations.

Creating the biggest waves in the industry

The Yeppoon prototype produced the biggest waves seen in a surf park to date. Wave heights over 2.4 metres showcased Surf Lakes’ infamous ‘Island Slab’ – known for producing thick barrels that broke boards, challenged pro surfers, and struck awe into spectators.

The largest stroke height (distance the plunger moves up and down to create waves) reached in the prototype was 4.8m. The commercial machine has been upgraded to a maximum stroke height of 5.5m, unlocking 20% of additional power that will set new standards.

Summary

Surf Lakes upgraded commercial technology, combined with Surf Lakes’ unique 360° design, promises unmatched wave quality and productivity – the likes of which have yet to be seen in the surf park market.

Kit Sidwell, Head of Research and Development at Surf Lakes, explains;

“We don’t compare Surf Lakes to other surf parks. We’re really just trying to replicate the ocean, and it’s the wave that really is the hero. We have a system that produces very powerful waves, and they carry that power down the line, and every surfer can feel that.”

While this new machine upgrade is an exciting prospect, there are many additional topics we’ll be unpacking in forthcoming blog posts. The unique way in which Surf Lakes generates waves, the Computational Fluid Dynamics (CFD) that goes into developing the reefs, water treatment, monitoring systems, and scalability, to name a few. With such a unique technology, there is a lot of specialised detail to delve into. We’re looking forward to sharing more, so stay tuned.

Licensee Inquiry Form

Don’t miss the opportunity to secure exclusive rights to your preferred territory. Register today for access to our Licensee information packs.

"*" indicates required fields